String construction

The end of the string that mounts to the instrument's tuning mechanism (the part of the instrument which can be turned to tighten or loosen the tension of the string) is usually plain. Depending on the instrument, the string's other, fixed end may have either a plain, loop, or ball end (a short brass cylinder) that attaches the string at the end opposite the tuning mechanism. When a ball or loop is used with a guitar, this ensures that the string stays fixed in the bridge of the guitar. When a ball or loop is used with a violin-family instrument, this keeps the string end fixed in the tailpiece. Fender Bullet strings have a larger cylinder for more stable tuning on guitars equipped with synchronized tremolo systems. Strings for some instruments may be wrapped with silk at the ends to protect the string. The color and pattern of the silk often identifies attributes of the string, such as manufacturer, size, intended pitch, etc.

Winding types

There are several varieties of wound strings available.

Roundwound

The simplest wound strings are roundwound?with round wire wrapped in a tight spiral around either a round or hexagonal core. Such strings are usually simple to manufacture and the least expensive. They have several drawbacks, however:

- Roundwound strings have a bumpy surface profile (the bumps of the winding) that produce friction on the player's fingertips. This causes squeaking sounds when the player's fingers slide over the strings, especially when used on electric guitar with a guitar amplifier or with an acoustic guitar amplified through a PA system. (Some artists use this sound creatively, such as hardcore punk and heavy metal music electric guitarists who scrape the pick down the lower-pitched strings for an effect.)

- Roundwound strings' higher friction surface profile may hasten fingerboard and fret wear, compared with smoother flatwound strings.

- When the core is round, the winding is less secure and may rotate freely around the core, especially if the winding is damaged after use.

Flatwound

Flatwound strings also have either a round or hex core. However, the winding wire has a rounded square cross-section that has a shallower profile (in cross-section) when tightly wound. This makes for more comfortable playing, and decreased wear for frets and fretboards (this makes them a popular choice for fretless instruments). Squeaking sounds due to fingers sliding along the strings are also decreased significantly. Flatwound strings also have a longer playable life because of smaller grooves for dirt and oil to build up in.

On the other hand, flatwound strings sound less bright than roundwounds and tend to be harder to bend. Flatwounds also usually cost more than roundwounds because of less demand, less production, and higher overhead costs. Manufacturing is also more difficult, as precise alignment of the flat sides of the winding must be maintained (some rotation of the winding on roundwound strings is acceptable).

Halfwound, ground wound, pressure wound

Halfwound strings, ground wound strings, or pressure wound strings are a cross between roundwound and flatwound. Such strings are usually made by winding round wire around a round or hex core first, then polishing, grinding (thus the name, ground wound) or pressing the exterior part of the winding until it is practically flat. This results in the flat, comfortable playing feel of flatwounds, along with less squeaking, with a brightness generally between roundwounds and flatwounds. The polishing process removes almost half of the winding wire's mass, thus, to compensate for it, manufacturers use winding wire of a heavier gauge. Because of the extra manufacturing process involved they are normally more expensive than roundwounds, but less than flatwounds.

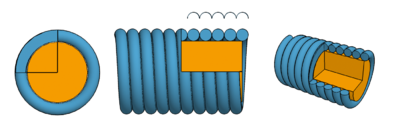

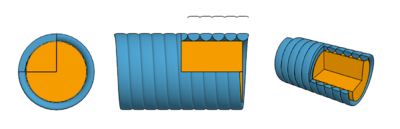

Core Types

There are two types, or shapes, of core wire typically used in wound strings.

Hexcore

Hexcore strings are composed of hexagonal core wire and a tight (usually round) winding. Hexcore string design prevents the winding from slipping around the core ? which can occur with round core strings. This may lead to improved tuning stability, flexibility, and reduced string breakage, compared with round core strings.

Round core

Round core strings are composed of regular round core and a tight (usually round) winding. Round core is the traditional "vintage" way of manufacturing and results in a greater contact between the winding and the core of the string.

Niciun comentariu:

Trimiteți un comentariu